Today we wrap up our 7-part series with Step #7, Order Validity Analysis. The final piece of the demand planning pie — where profitable, efficient orders happen.

Today we wrap up our 7-part series with Step #7, Order Validity Analysis. The final piece of the demand planning pie — where profitable, efficient orders happen.

Order Validity Analysis allows you to place an order that makes sense for your receiving team, keeps your line in balance, and ensures that the order comes due in harmony the next time.

Order Validity Analysis happens after basic replenishment, and after you have taken advantage of any deals, prepared for promotions, and considered overstock options.

- Demand Forecasting

- Lead Time Forecasting

- Order Cycle Optimization

- Service Level Management

- Replenishment

- Special Order Analysis

- Order Validity Analysis

Optimized Buying Multiples, Balanced Orders, Intelligent Brackets

Best-in-class demand planning carries the process through to completion for inventory teams. There should not be a need for manual adjustments for buying multiples, or for building to brackets.

Finish the order by executing the previous established, intelligent parameters.

#7 is Executing the Chosen Elements of #3: Order Cycle Optimization

It’s important to recognize that Element #7 is a process of executing the decisions already made during Element #3: Order Cycle Optimization. During Element #3, you chose the most profitable Order Cycle, as well as the most profitable Order Minimum or Bracket. You also made sure that the chosen Order Cycle time supply matched the chosen Bracket.

It’s important to recognize that Element #7 is a process of executing the decisions already made during Element #3: Order Cycle Optimization. During Element #3, you chose the most profitable Order Cycle, as well as the most profitable Order Minimum or Bracket. You also made sure that the chosen Order Cycle time supply matched the chosen Bracket.

For example, if the most profitable bracket is a truckload, and it takes 10 days to sell a truckload of product, then the Order Cycle must be 10 days.

During Element #7, you ensure that the order total matches the chosen bracket of a truckload. In addition, you’ve already chosen item Buying Multiples and even Convenience Multiples for each item. During Element #7, you will round the order quantities required to their chosen multiples.

Element #7 is not a time for last-minute changes due to freelance rounding to multiples. It is a time to execute the plan.

Three Main Areas of Focus:

- Adhere to the Chosen Bracket

- Build Days in Balance to the Chosen Bracket

- Round Item Quantities to Buying Multiples & Convenience Multiples

Adhere to the Chosen Bracket

Through the first 5 elements, you created order quantities needed to maintain your service level goals. In the 6th element, you adjusted items for any deals, planned promotions and overstock balancing decisions.

Now it’s time to add up all of those quantities and see how the totals compare to the bracket requirements. These are streamlined, important decisions in this final stretch.

Your needs total 38,000 lbs. The chosen bracket is 44,000 lbs. There is still work to be done!

Build Days in Balance to the Chosen Bracket

Building days in balance is the key.

Avoid simply adding quantity to your top item or two to achieve the total. This puts the line out of balance. And after doing this for a few orders in a row, you will have so much excess of those A items, that you won’t have enough weight to build an order. All other items will be harmed.

Remember, one of the most important goals you have in this process is to build the order in such a way that you are well prepared for the next order. You are preparing for the next order as much as you are trying to complete this order.

Both goals are equally as important.

To build the order up, you will increase your Vendor Order Point, as well as your Order Up To Level one day at a time (or a fractional day at a time).

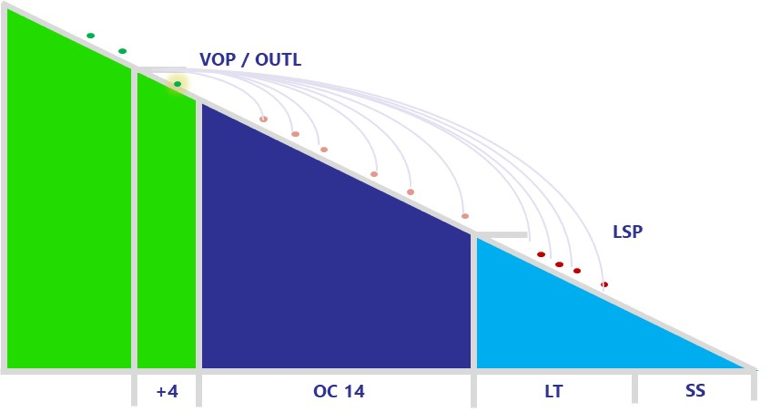

The obvious move is to increase the OUTL for each item being bought; however, this is not enough. As shown in the visual above, this example required 4 additional days to reach the truckload bracket. By also increasing the Vendor Order Point, some items that were not previously needed on the order are now needed.

This is one of the critical steps that keeps the line balanced.

There are 2 pitfalls you need to watch out for here: mismatch and strategy change…

AVOID Mismatch: If you find that you are continuously adding numerous days’ supply to achieve the minimum or bracket, it is possible that your Order Cycle is not set properly to match the bracket. Once you know that you have to achieve a minimum or bracket, you have to make sure the days’ supply matches it.

AVOID Strategy Change: This final step is not the time to determine that which bracket is right for you. That decision should have occurred during Element #3 – Order Cycle Optimization. Once that bracket is chosen, the Order Cycle was set to match it.

There may be unique times of the year where you will decide to make unique decisions, or even to forego a bracket to bring in needed items when achieving

the bracket requires too many days. This can occur after large forward-buy orders have been placed.

Round Item Quantities to Buying Multiples & Convenience Multiples

As the items are moving up the depletion graph to achieve the supplier minimum or bracket, each item also has to abide by its chosen rounding multiple rules.

The obvious process is to adjust each order quantity to round to the buying multiple. The more important Buying Multiple decision should have happened back during Element #3: Order Cycle Analysis.

Many items have several choices of buying multiples, including eaches, cases, layers and pallets. Some suppliers force requirements on certain items. These requirements can lead to critical decisions of centrally stocking the item, or even not stocking the item.

Some items also have unique item minimums. This is most common with private-label suppliers who have to make special equipment adjustments to their manufacturing processes.

Time to Revisit Your Buying Multiple Strategy

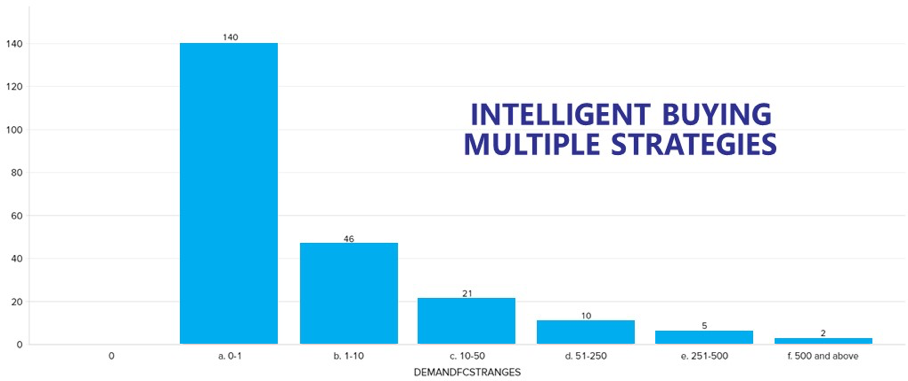

It is important to choose intelligent and financially smart buying multiples. The following Buying Multiple strategy has been deployed by a best-in-class inventory team in the foodservice distribution industry.

You see a cascading approach where the faster moving items, which are likely holding the most dollars, are rounding to only 2 days supply. This keeps the line balanced and the items closest to the Order Up To Level when replenishing.

Watch for These Buying Multiple Pitfalls…

Watch for These Buying Multiple Pitfalls…

Buying Multiples Take the Lead: The Buying Multiple becomes the Order Cycle. Normally, your supplier order cycles drive your replenishment, but when A-items have large buying multiples in days, those buying multiple become the true order cycle, and it is much higher. This drives inventory up.

You might think your Order Cycle is 14 days, but your Effective Order Cycle might actually be 21 days due to high buying multiples on A items.

Out of Balance: Inconsistent Buying Multiple Days throws the line out of balance. When a line is replenished, your strategy is trying to buy everything to the same Order Up To Level. If all of your items in the supplier line sit at high buying multiple days, they will also all be at different buying multiple days. This leads to heavy inventories.

Too Much Topping Off of Your High-Inventory A-Items: Often many A-items sit just a few days below the Order Up To Level with very little need. However, when they are replenished back up, they are forced to go many days or weeks beyond the desired Order Up To Level.

These high inventory items are being ‘topped off’ and never deplete down to the lower level where they could be living. This also leads to heavier inventories.

The Key to Smart Multiples is Smart Convenience Multiples

The key to not applying costly, high buying multiples is to apply a Convenience Multiple option.

Trying to choose between buying in layers and pallets? Set your Buying Multiple to layers and apply a pallet-level Convenience Multiple.

When the need drives the order quantity close to the pallet, make the jump to the pallet size. Best-in-class demand forecasting solutions will have this feature, and will allow you to set your ‘aggressiveness level’ of when to make the jump.

Great demand planning teams set smart Buying Multiples and Convenience Multiples and adjust them as the demand changes, including seasonal adjustments. Processes can be put in place to make this process very fluid.

Success Will Come from Finishing the Process with Great Precision

Avoid emotional and tactical decisions and allow your #3 Order Cycle strategy settings to work. Watch for the pitfalls of too many days added to an order, and rounding too high on expensive A items.

These 7 Essential Elements will help you avoid numerous demand planning snafus and deliver rapid results in service, inventory and profit.

Even the top inventory teams in the world continually challenge their level of excellence in each element. How about you? Are you set for excellence in each element?