Fixed Cycle Buying is the silent producer of excess inventory.

Your suppliers that have been set to replenish on a fixed cycle like ‘every Monday’ or ‘every other Wednesday’ are tying up 20% or more in dollars that could be invested more profitably.

Today we’ll show a replenishment breakdown, talk you through some reasons why lines are set as fixed, and suggest demand planning and inventory reduction strategies to make sure the whole company is working toward getting your fixed cycle benefits to exceed the expense.

Order Cycle Breakdown: The excess is silent, hidden and surprising

Inventory excess happens when the order cycle, bracket and demand do not match.

Fixed cycles are typically set on larger, more influential suppliers. These suppliers are more likely to be bought to bracket sizes or minimums in weight, cube or dollars. However, those brackets or minimums actually make up a specific time supply.

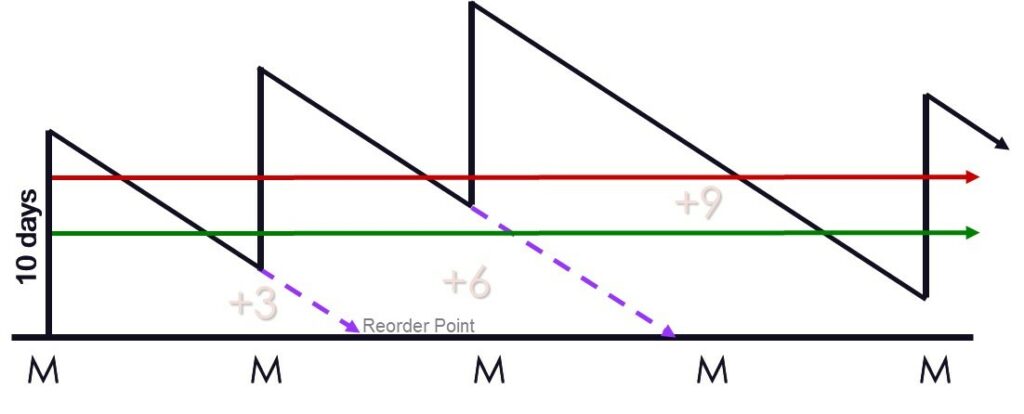

For example, a truckload of product on a supplier might represent 10 days’ worth of demand like in the visual. You don’t control the size of the truck or the demand.

When you establish a fixed cycle, you try to control the replenishment process, and that is where the damage occurs. In the scenario below, the supplier is set to replenish every Monday:

The green line represents the inventory level possible if you allowed the replenishment to respond to demand and buy when needed. The red line shows your actual inventory based on the fixed-cycle build up.

On the first Monday, a truckload is purchased, which is 10-day supply. Those goods want to deplete down and replenish together in about 10 days, which would be approximately the following Thursday.

However, between now and then, Monday happens. Even though you are sitting on about 3 days too much inventory, you replenish again. You again replenish a truckload of product, which is a 10-day supply. You are now sitting about 13 days above your re-order position.

On the next Monday, you do analysis to see if you can skip a week. However, as the image shows, you are sitting with 6 days too much inventory, which is not yet enough to allow you to skip an order. So another truckload order is placed.

Finally, the inventory has built up so much that you can skip the next Monday order, and start the build-up process again the following Monday.

The impact: The green line represents the inventory level possible if you allowed the replenishment to respond to demand and buy when needed. The red line shows your actual inventory based on the fixed-cycle build-up. To learn more about how fixed cycle buying steals profits from distributors, go here.

In a fixed REPLENISHMENT scenario, you are either buying too early or too late

Even if you don’t have to adhere to a bracket or minimum size, you will experience a build-up of inventory.

For every fixed-cycle supplier, you make weekly decisions to either buy now or wait. You decide whether to gamble on service levels and wait, or to play it safe and buy early. You rarely find that the fixed cycle day is also the exact perfect day to replenish.

In our experience, and after many years of watching inventory professionals who are responsible for maintaining the service image of the company, you don’t gamble. All it takes is one lost gamble, and the backlash of running out of stock will influence your decisions in the future.

There is only one way to say it… On fixed cycle buying, you always buy early.

That week where you can skip an order can really hurt

The week where you have no order to place should feel uncomfortable. It means that the inventory is higher than you would prefer, and you are waiting for it to come back to an area of normal. However, that’s typically not the worst part.

Unless you are using one of today’s best-in-class solutions for demand planning, you are at extreme risk for experiencing unpleasant out-of-stocks.

These don’t normally occur on your A-items, as you likely made sure they have plenty of supply. The problem is in the C and D, and surprisingly seasonal items.

READ: The Growing List of Surprisingly Seasonal Items

Those items have challenging seasonal demand patterns and require the most sophisticated forecasting, safety stock and profiling tools.

Without a unique and intelligent strategy on every item, you will experience service challenges during that two-week window.

Why do we believe there is 20% excess?

Our bold statement is influenced by more than the image above. The inventory community is a powerful source of education, experience and suggestions.

Many demand planning professionals and inventory teams have realized this level of inventory reduction savings after eliminating fixed-cycle replenishment on supplier lines. After a few cycles, the inventory reduction will be realized, and will become the new normal.

The Source: Fixed cycles are established for numerous reasons

There are several very common sources that request fixed-cycle replenishment. Some reasons are good, but many are not good enough.

Suppliers often demand fixed cycle replenishment

Your suppliers often prefer to plan their orders and operations. They will ask, inspire or even demand that you fall in line with what works best for them. They benefit by planning their production, operations and labor.

How do you benefit?

[Crickets].There’s really nothing in it for you unless they are offering a quality discount for buying in their pattern. Some of your suppliers are powerful enough to put you in this costly situation, but others need to finally offer financial gain, or allow you to replenish the way you want. Even the big players need to realize the price you are paying. Your margins are already slim.

How about your customers? Do they buy from you when they want, or when you require?

Best-in-class demand planning solutions show you the money

These advanced applications are financially based and show the exact annual profit lost to these fixed cycle buying patterns. Distributors use this information to either avoid these pitfalls, or to win the rebates or pricing required to pay for the excess inventory.

The transportation department often requests fixed cycle buying

Your transportation teams have operational goals similar to your suppliers. They like to adhere to a schedule, and they work to find back-haul or brokerage carriers to reduce freight costs.

This is an ideal opportunity to work together. Start by educating them on the expensive impact of fixed cycle buying. Work together to compare the transportation savings with the cost of the excess inventory.

Your transportation team is working to show a savings through back-haul or brokers, and you need to team up to avoid sub-optimization. You both need each other. And if you work together, you can create common goals that can be measured in your income statement.

A best-in-class demand planning solution can help find those ideal situations through advanced bracket analysis.

Your team champion or team leader should offer to spend time learning in the transportation area, and you should invite their team leaders to spend days with your inventory team. All goals need to become company goals, not just department goals.

Perhaps you simply like the convenience

You may be cursing this article right now. You might like the convenience of setting a schedule of ordering so that you can plan your days and weeks. It makes your inventory life more comfortable. However, now that you have seen the picture, you can’t be comfortable because you won’t be able to replenish guilt-free.

If you have set fixed cycles to make your life work better, you are replenishing too early the vast majority of the time. Your inventory is sitting much higher than it needs to be.

Now is your opportunity to deliver heroic results. Your role is about to become more challenging, but you will deliver valuable cash back to the organization. You will win.

Move away from fixed-cycle replenishment wherever you can and reap the rewards.

You don’t have the right demand planning tools

If you are still living on elaborate spreadsheets or ERP buying reports and tools, you might feel lucky just to get through each week.

One of the most common and expensive pitfalls of not having a true demand planning solution is that you are stuck buying on a schedule.

If your inventory solution does not look at every item and every supplier every night, and tell you exactly which lines need to be replenished to maintain service levels, then all of your replenishment is adhering to this expensive habit.

If this is the case, your inventory problems go far beyond the excess inventory caused from fixed cycles that are purchased too early. You are facing a lineup of costly pitfalls. Your inventory will stay high and your service issues will continue on uniquely challenging items.

Use this as motivator. Make this the start of your ROI analysis on a journey to best-in-class inventory planning.

Move forward intelligently; make financially smart replenishment decisions

Some retail and wholesale distributors have completely eliminated fixed cycle buying, but many still have some lines that remain with this strategy. Most inventory teams have experienced great results where they are able to make the change.

Once you experience the inventory reduction from suppliers that are removed from fixed cycle replenishment, it will inspire you to work hard to move other suppliers to replenish based on need.

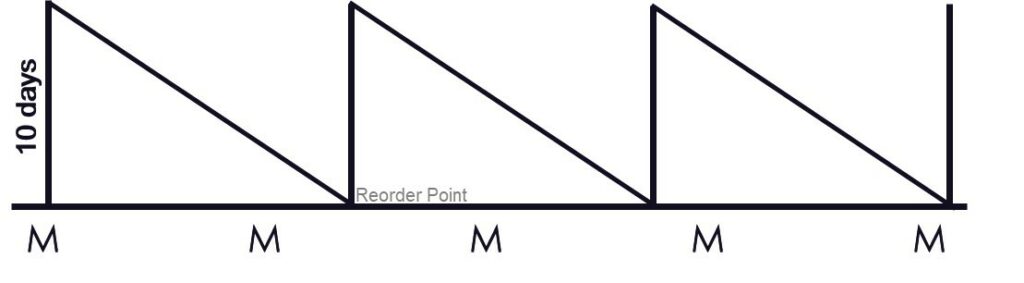

The image below shows a 10-day ordering cycle that is replenishing based on need while adhering to the required bracket. As we shared in a previous article on inventory reduction, the key to lowering inventory is not to buy less; it is to ‘buy later’.

Replenish when your items want to buy, and not when you or your suppliers prefer to buy.

Those who have moved the majority of their replenishment to buying on need have been pleased to see that it has actually resulted in a smoothing of receiving also. It is a more coordinated flow of supply and demand.

Those who have moved the majority of their replenishment to buying on need have been pleased to see that it has actually resulted in a smoothing of receiving also. It is a more coordinated flow of supply and demand.

Watch related video: Inventory Reduction Strategy 101: The Problem with Fixed Cycle Buying

Inventory reduction will happen

Now you know the truth. You are looking at the top picture and recognizing the pattern in your world. See it as good news. View it as newly found cash about to happen.

Invite the other leaders in the organization to understand the cost of excess inventory caused by fixed cycle buying. A picture is worth thousands, or even millions, of dollars.

Work on changing the strategy as a team. Make each decision a financially sound inventory decision. Eliminate fixed cycle replenishment, or make it pay off!

Related:

Inventory Reduction Strategy 101: The Problem with Fixed Cycle Buying